A global knowledge ecosystem of students, professionals & industry-leaders to share, create, and mentor experiences

contact@podareduspace.org

+91 98202 27795

EVs - The next big thing in saving the environment by Vidur Jhunjhunwala

This study investigated the background characteristics and environmental impacts of EVs with an emphasis on their potential in the Indian market.

EV- The next big thing in saving the environmentELECTRIC VEHICLE

The Primary components of a Battery Electric Vehicle (BEV) are

• The Battery Pack

• Inverter

• Electric Motor

• Controller

• Charger

• Charging Cable

Battery Pack

A BEVs range, propulsion and all its other features depend solely on the battery pack for power. BEVs use high voltage batteries (HV) to power them. The battery pack is built by connecting thousands of these cells in series and parallel to achieve the required amount of current output from these cells.

An energy source like a battery needs to satisfy two important criteria-energy density and power density. These along with other features like easy maintenance, long life, inexpensive and fast charging. There are various batteries which have been used for BEVS. Few include lead-acid, Ni- Cd, Li-ion. The most common battery used in BEVs are Li- ion batteries. However, the industry is slowly drifting towards Na – ion batteries which are more efficient than

Li-ion. 5

The figure depicts the multiple battery cells used in EV battery packs. In the Tesla Model S, cells are arranged into different modules. 16 of these modules are then connected in series and parallel to achieve the desired power output. Metallic inner tubes are passed through the gaps between the cells in which glycol coolant is passed through to prevent overheating of the batteries.

The benefit of using multiple smaller cells instead of fewer big cells is the temperature is maintained evenly preventing thermal hotspots in the case of the small cells. Even temperature distribution results in higher battery life.

The low height of the battery pack fitted close to the ground level, lowers the vehicles center of gravity which provides extra stability to the vehicle. The battery pack is also spread across the floor allowing for structural stability and protection from side collisions.

As said earlier Lithium - ion cells are the most used cells for BEVs currently, they work on the principal of converting chemical energy to electrical energy via redox reactions.

Understanding the functioning of Lithium-ion Cells (LICs) requires knowledge of lithium's properties that allow it to function as a cell. Lithium atoms are very reactive and easily give away their lone electron from the outermost shell. In contrast, lithium oxides are extremely stable

compounds.

Once the lithium atom is removed from its oxide, it becomes very unstable and easily gives away its outer electron. When there is a designated route for both the electron and the lithium-ion to reach the metal oxide separately, the lithium- ion will combine with the oxide while the electron moving towards the oxide will produce electric power. This is the fundamental concept that LICs function based on.

An LIC is composed of a cathode, an anode, a separator, and two current collectors, usually constructed from copper and aluminum.

7

The graphite anode is typically referred to as the anode or negative terminal. The ring structure of graphite enables lithium ions to intercalate between its layers.

The lithium metal oxide used as the cathode, also known as the positive terminal, is typically lithium cobalt oxide or lithium manganese oxide.

Organic solvents usually contain lithium hexafluorophosphate as the electrolyte. This electrolyte is applied onto a partially permeable separator, allowing lithium ions to move between electrodes while blocking electron flow.

Copper and aluminum current collectors have cathode and anode coatings applied to them. While charging, current goes to the cathode, leading to the separation of lithium ions from the oxide and their movement towards the anode via the electrolyte and separator. At the same time, electrons move through the external circuit to reach the anode and insert themselves into the graphite.

While the battery is discharging, electricity is produced as electrons move from the anode to the cathode, powering the device, and lithium ions travel towards the cathode and embed themselves into the oxide material. This process is how an LIC generates power.

Motor and Engine

BEVs utilize motors instead of traditional Internal Combustion Engines to propel the vehicles. Electric vehicles are typically powered by either permanent magnet synchronous motors (PMSM) or induction motors (IM).

PMSM

It operates based on a magnetic field that moves and another magnetic field that remains constant. An electric motor is made up of two main components.

The stationary part and the rotating part

The stator is supplied with three phase alternating current, resulting in a rotating magnetic field within the stator. Synchronous speed (Ns) is the speeds at which the magnetic field revolves.

The rotor consists of aluminum bars, permanent magnets, and silicon steel laminations.

Placing the rotor inside the stator results in the generation of a current induced by the rotating magnetic field, leading to a torque that causes the rotor to rotate in sync with the magnetic field.

The permanent magnet's opposite poles and the rotating magnetic field are attracted to each other, becoming magnetically locked and causing the rotor to turn until it reaches synchronous speed.

The rotor's mechanical energy is transferred to the wheels, resulting in their rotation.

Ns=120f/P f- frequency of electricity

P- number of poles

Inverter

The inverter converts the DC supply from the battery to AC for the motor. The frequency of the current supplied can be altered by the inverter hence changing the speed of the car.

The inverter also plays a role in the regenerative braking system.

When there is no signal from the accelerator, the kinetic energy of the car is converted to electrical energy which is converted to DC voltage and adjusted to fit the batteries requirements charging the batteries. The inverter constantly alters the frequency of the AC current supplied to the stator as the rotor is slowing down, hence braking.

Charging

Electric vehicles (EVs) have the capability to connect to charging systems powered by either alternating current (AC) or direct current (DC). These systems are available in various configurations, commonly known as "levels." The amount of time required for your EV to be fully charged depends on the level you select. Chargers must also adhere to safety standards.

Charging using alternating current.

AC

AC charging stations utilize a converter integrated within them to convert AC power received from the grid into DC power for charging the battery. The SAE has set various power levels for AC EV charging.

•Level 1 offers the lowest speed, delivering either 12 amps or 16 amps based on the circuit, with a top voltage of 120 volts.Level 1 charging is appropriate for charging overnight, especially for smaller EVs, and can require up to 12.5 hours to fully charge.

• Level 2 charging is the most frequently used method for

electric vehicles. A special charging station called Electric Vehicle Supply Equipment (EVSE) is needed for a direct connection to the electrical grid. The electric vehicle has its own built-in charger which changes alternating current into direct current. Level 2 chargers provide 240 volts and up to 60 amps, resulting in a maximum power output of 14.4 kW. This enables charging at a significantly faster rate than Level 1.

• Level 3 is the high-powered choice made for use at public

charging stations. These are fixed in place and connected to supply over 14.4 kW of power. For instance, quick chargers can greatly decrease charging durations, frequently refilling an electric vehicle battery in approximately 30 minutes.

DC

In contrast to AC charging, DC systems provide a faster charging option for electric vehicles (EVs). These systems need special electrical wiring for higher power output and can be set up in either home garages or public charging stations. DC charging systems are classified based on the power they provide, ranging across various levels.

• Level 1 (Up to 36 kW): Although the slowest DC option available, it could still be useful for occasional charging needs.

• Level 2 (Up to 90 kW): This level is frequently used and provides a nice equilibrium between charging rate and power needs.

• Level 3 (Up to 240 kW): These chargers are the strongest DC fast chargers available, cutting down on charging times but necessitating unique infrastructure.

EV owners can optimize their charging experience by selecting the appropriate DC charging level that suits their needs and infrastructure access.

ADVANTAGES OF EVs

1)EVs offer a clear environmental benefit. They produce zero tailpipe emissions eliminating harmful pollutants like CO2, SO2, NOX etc. This is particularly impactful in urban areas where traffic congestion can arouse further air quality issues. Though the electricity provided to the EVs is majorly from fossil fuels and other indirect emissions, in the long run the environmental harms are much lesser than ICEs. As the electricity transitions towards renewable sources the environmental benefits of EVs increase further.

“A major concern about electric vehicles is that the supply chain, including the mining and processing of raw materials and the manufacturing of batteries, is far from clean,” says Gillingham. “So, if we priced the carbon embodied in these processes, the expectation is electric vehicles would be exorbitantly expensive. It turns out that’s not the case; if you level the playing field by also pricing the carbon in the fossil fuel vehicle supply chain, electric vehicle sales would actually increase.”

2)Though EVs cost more upfront, the long-term cost of EVs is lesser than their ICE counterparts due to easy maintenance especially if charged at home. EVs do not require oil changes, spark plug replacements and electricity costs per unit are generally lower than gasoline. If charged overnight when demand of electricity is low this cost becomes even lower. For these reasons many shipping companies are transitioning their shipment trucks to electric vehicles due to cheaper long-term price

3) EVs provide an instant torque and remains constant for a longer period, while providing almost similar power as ICE as the energy generated by the motor is given directly to the wheels hence allowing for peak output immediately.

Risks of EVs

Limited Range and Charging Infrastructure: One of the major concerns for potential EV buyers is range anxiety, the fear that an electric vehicle will run out of battery before reaching its destination. Although modern EVs have improved their range capabilities, they still fall short when compared to the distance that ICE vehicles can travel on a single tank of fuel. Moreover, the availability of charging infrastructure remains a significant challenge. In many regions, there are not enough charging stations, and those that exist may not be conveniently located or may offer slow charging speeds. This infrastructure gap makes long-distance travel and even daily use less convenient for EV owners, potentially limiting the widespread adoption of electric vehicles.

Battery Degradation and Disposal Over time: the batteries in electric vehicles degrade, losing their capacity and efficiency. This degradation can result in reduced driving range and overall vehicle performance, necessitating costly battery replacements. The lifecycle of an EV battery is typically around 8-10 years, after which it may need to be replaced, adding to the total cost of ownership. Additionally, the disposal and recycling of used EV batteries present significant environmental challenges. Batteries contain hazardous materials that require careful handling and processing to avoid environmental contamination. While recycling technologies are improving, the infrastructure for large-scale battery recycling is still developing, posing potential environmental and logistical issues.

Impact on Stakeholders who Lose Out

Oil and Gas Industry: The shift towards electric vehicles directly impacts the demand for oil and gasoline, which are the primary fuels for internal combustion engine vehicles.

As more consumers adopt EVs, the demand for fossil fuels decreases, leading to lower revenues for oil producers, refiners, and distributors. This reduction in demand can also affect global oil prices, creating market volatility and financial instability within the oil sector. Companies in this industry may face significant financial losses and may need to diversify their business models to remain viable in a future dominated by electric transportation.

Traditional Automotive Industry Manufacturers that have historically focused on producing ICE vehicles may struggle to adapt quickly to the electric vehicle market. This transition requires substantial investment in new technologies, manufacturing processes, and workforce training. Companies that fail to adapt may lose market share and revenue. Additionally, suppliers of components specific to ICE vehicles, such as engines, transmissions, and exhaust systems, may see a decline in demand for their products. This shift can lead to job losses and economic disruptions in regions heavily dependent on ICE vehicle production and related industries.

EVs in India

Electric vehicles (EVs) in India represent one of the most rapidly growing and promising industries. As of 2023, EVs accounted for 6.5% of all vehicles in the country. According to the Indian Ministry of Road Transport and Highways, there were 1,334,385 electric vehicles on Indian roads by July 2022. India's ambitious goal is to have 30% of all vehicles be electric by 2030, a target that underscores its bold approach to reducing oil dependency. This shift could significantly impact global oil prices and market trends, given India's status as the world's third-largest oil importer.

The country's strategy for electric vehicles carries significant global ramifications, given its rapidly expanding economy and population. A successful transition in India could serve as a model for other developing nations, potentially accelerating the decline in global oil consumption. As India advances towards cleaner energy and better battery and charging technology, the market for EVs is expected to rise exponentially.

Currently, leading EV manufacturers in India include Tata

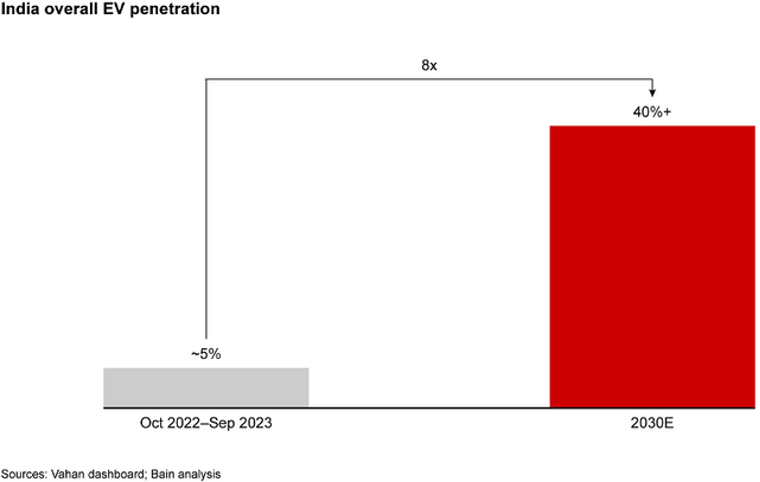

Motors, with models like the Nexon EV, Tigor EV, and Tiago EV; Mahindra Electric, with the eVerito and the e2oPlus; and MG Motor India, with the MG ZS EV. The Indian EV market is at an inflection point, with EVs accounting for about 5% of total vehicle sales between October 2022 and September 2023.

This penetration could exceed 40% by 2030, driven by strong adoption rates exceeding 45% in both the two-wheeler (2W) and three-wheeler (3W) categories. Despite this potential, several structural challenges need to be addressed to spur increased EV adoption.

These challenges include the higher price of EVs compared to internal combustion engine (ICE) vehicles, range anxiety, limitations in charging infrastructure, and friction in customer financing. Companies like Hyundai plan to invest close to $4 billion in the Indian market over the next decade, focusing on launching new EVs, establishing charging stations, and setting up a battery pack assembly unit.

Maruti Suzuki India, the country's top automaker by sales, also plans to have six EV models by 2030. Currently, 2W EVs form most EV sales, accounting for 85%–90% of all EV units sold in India, followed by 4W EVs (7%–9% of sales) and 3W EVs (5%–7% of sales). The Faster Adoption and Manufacturing of Electric Vehicles (FAME) scheme's Phase II revision saw 2W EV penetration remain stable at around 5%, consistent with January-March 2023 levels. In contrast, 3W EV and 4W EV penetration levels experienced significant growth, with volumes more than doubling over the past 12 months due to their low total cost of ownership (TCO).

India is home to numerous electric vehicle makers, offering a range of products from electric cars to scooters, catering to various needs and financial situations. The Indian government's ongoing support for electric vehicles suggests that the number of EVs on Indian streets will continue to rise soon. With significant investments from major automakers and continued innovation in EV technology, India is poised to become a global leader in electric vehicle adoption, setting a precedent for other nations to follow.

Conclusion

In conclusion. The economic and environmental issues brought about by our reliance on traditional internal combustion engine (ICE) vehicles are compellingly addressed by the rise of electric vehicles (EVs). This study investigated the background characteristics and environmental impacts of EVs with an emphasis on their potential in the Indian market. The primary battery electric vehicle (BEV) components—the battery pack inverter electric motor controller charger and charging cable—were examined in the study. Focusing on this aspect of EV power sources established an understanding of lithium-ion battery technology and operation. Furthermore, knowledge of permanent magnet synchronous motors (PMSMs) and induction motors (IMs) illuminates the workings of the electric vehicle powertrain. An important objective was to investigate the environmental advantages of electric cars.

Even though electric cars don’t emit any pollutants into the atmosphere when they drive the article acknowledged that burning fossil fuels to produce electricity typically results in the release of additional emissions. But the long-term environmental advantages of electric cars were emphasized especially as the grid shifts to more sustainable energy sources. The article also discussed how electric vehicles may help to lessen noise pollution in urban areas. The study finds that although the initial costs of electric vehicles may be higher than those of cars with internal combustion engines over time the overall operating costs of EVs are lower. This can be explained by the fact that electricity is less expensive per unit than fuel and requires less maintenance. Furthermore, the topic of how large corporations like shipping companies could save money by converting to an electric fleet was covered. The advantages of this move were considered including the potential to set an example for other developing nations and a significant reduction in India’s reliance on oil. In summary electric cars present a viable future route for a more environmentally conscious transportation sector. Despite obstacles, government support, infrastructure for charging and advancements in battery technology are enabling a greater uptake of electric vehicles. India has a significant opportunity to reduce its dependency on fossil fuels and serve as a model for other developing nations wishing to transition to more environmentally friendly and sustainable modes of transportation thanks to its ambitious electric vehicle (EV) targets.

References

2) https://www.energy.gov/energysaver/articles/how-lithium-ion-batteries- work#:~:text=The%20anode%20and%20cathode%20store,at%20the%20positive%20current%20collector.

3) https://www.youtube.com/watch?v=3SAxXUIre28&t=316s

4) https://batteryuniversity.com/article/bu-204-how-do-lithium-batteries-work

6) https://www.i4talk.com/threads/ice-vs-electric-power-and-torque-comparison.8801/

8) https://x-engineer.org/battery-electric-vehicle-bev/

9) https://www.sciencedirect.com/topics/engineering/battery-electric-vehicle

10) https://www.quora.com/Can-an-electric-motor-act-as-both-a-generator-and-an-alternator-If-so-what-are-some- conditions-under-which-this-would-happen

11)

12) https://www.chegg.com/homework-help/questions-and-answers/lithium-ion-batteries-use-two-half-reactions-whose- standard-reduction-potentials-shown--co-q11586133

13) https://auto.economictimes.indiatimes.com/news/auto-components/what-are-the-types-of-electric-motors-which- motor-suits-your-ev-the- best/102099884#:~:text=PMSM%20is%20the%20most%20popular,applied%20in%20high%2Dspeed%20applications. https://www.kia.com/uk/about/news/what-are-the-benefits-of-torque-in-electric- cars/#:~:text=Another%20key%20advantage%20of%20the,Internal%20Combustion%20Engine%20(ICE)

14) https://www.kia.com/uk/about/news/what-are-the-benefits-of-torque-in-electric- cars/#:~:text=Another%20key%20advantage%20of%20the,Internal%20Combustion%20Engine%20(ICE).15) https://afdc.energy.gov/fuels/electricity-stations

16) https://avt.inl.gov/sites/default/files/pdf/fsev/compare.pdf

17) https://www.youtube.com/watch?v=fUDq0yS0-Mk

19) https://cleantechnica.com/2022/02/26/gas-cars-produce-more-supply-chain-emissions-than-evs-yale-university- study/#:~:text=%E2%80%9CA%20major%20concern%20about%20electric,vehicles%20would%20be%20exorbitantly%20expensive. 20)https://www.bain.com/insights/india-electric-vehicle-report- 2023/#:~:text=India's%20electric%20vehicle%20(EV)%20market,%2Dwheeler%20(3W)%20categories.

21)https://www.india-briefing.com/news/indias-prospects-as-an-ev-hub-consumer-market-and-production-capacity-30157.html/ 22)https://jmkresearch.com/category/electricvehicle/#:~:text=Electric%20Vehicles-,6.5%25%20of%20total%20vehicles%20sold%20i n%20India%20in%202023%20were,during%20the%20last%20calendar%20year.

23) https://www.youtube.com/watch?v=stq2E3sZYg0

24) https://www.irjmets.com/uploadedfiles/paper/issue_5_may_2022/24839/final/fin_irjmets1653897083.pdf

25) https://www.iea.org/policies/6201-national-electric-mobility-mission-plan-nemmp

26) https://diyguru.org/faq/top-10-ev-manufacturers-in-india/

27) https://www.energy.gov/articles/history-electric-car

28) https://www.youtube.com/watch?v=-EG6rqA2vvA

29) https://www.youtube.com/watch?v=S6f1TbWRG3s

30) https://www.researchgate.net/figure/1-The-Structure-of-a-Permanent-Magnet-Synchronous-Motor_fig1_348740662/download?

tp=eyJjb250ZXh0Ijp7ImZpcnN0UGFnZSI6Il9kaXJlY3QiLCJwYWdlIjoiX2RpcmVjdCJ9fQ 31)https://www.researchgate.net/publication/364737960Electric_vehicles_a_review_of_their_components_and_technologies